BOP real-time monitoring is the gathering and monitoring of real-time BOP data using an independent, automatic, and continuous monitoring system capable of recording, storing, and transmitting data regarding the the BOP control system.

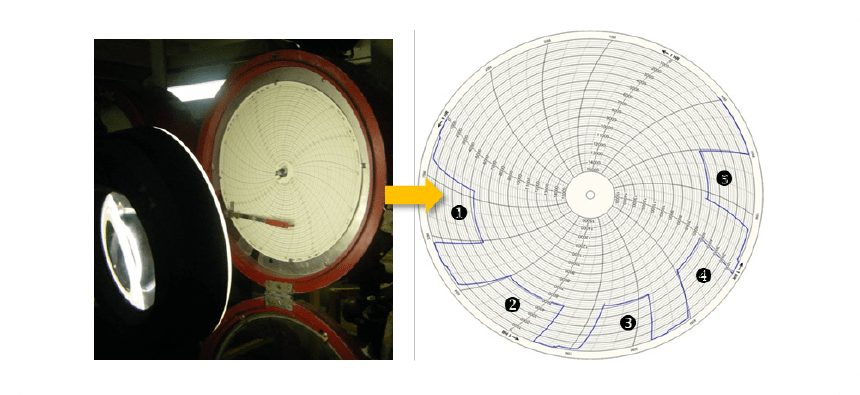

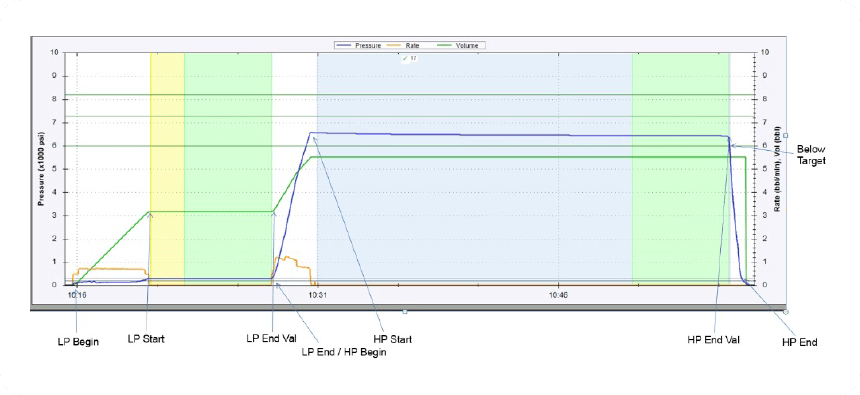

Sensory data accessed from the BOP Control system and supporting Control systems (Surface and Subsea) is streamed from the Rig. This data can be digital or analog tags that are produced from the OEM control system. Some examples of this data will be pressure, temperature, position, ground fault leakage, flow, alarms, faults, emergency modes, and PLC heartbeats.

Real-Time BOP control system and supporting control systems data is transmitted from the offshore rig to remote real-time monitoring using an internet connection via cloud based software and stored redundantly at a local secured server and remote data center. The real-time data feeds are properly maintained.

BOP control system and supporting control system data is broken down into individual signals and referred to as “tags”. These tags are labeled with specific OEM preferred addressing sequencing and Nomenclatures. Once the OEM labeled tags reach the IPT Global remote real-time monitoring center they are verified with active correlating functions, pressures, positions, etc.

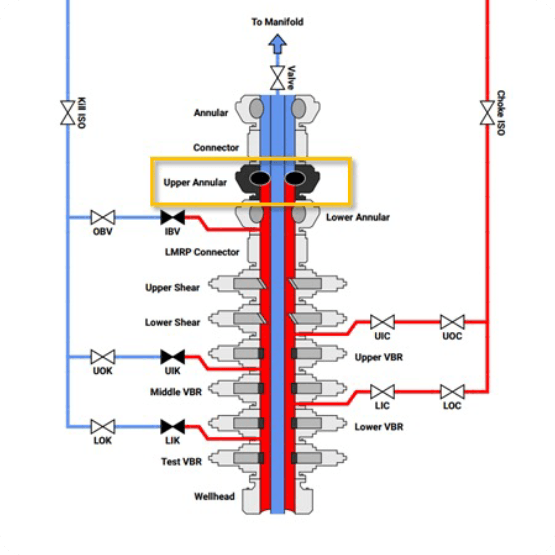

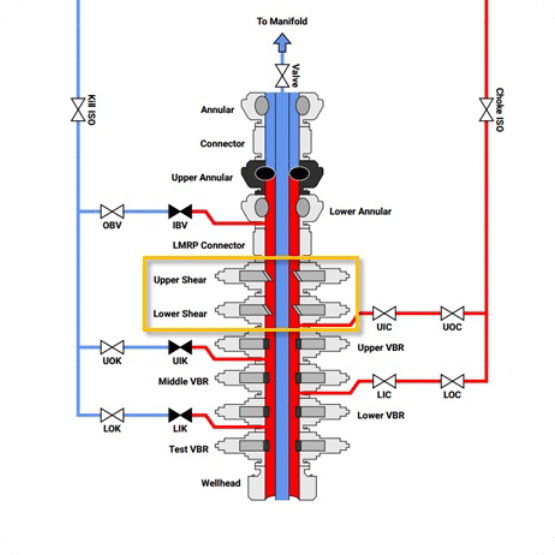

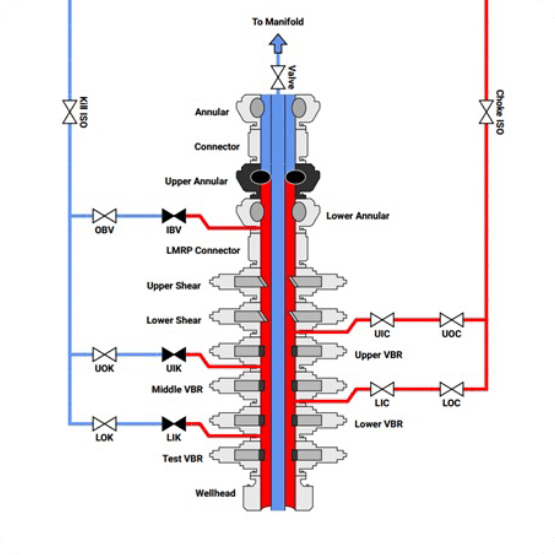

BOP analysts are seasoned Senior Subsea Engineers and/or Subsea Supervisors (who have been rigorously trained by WCSE RTM SMEs) monitor this data in real-time using IPT Global’s Digital Twin displays. Clients are provided with remote access to this data in real-time.

All BOP real-time data received is backed up and stored.