Enhance your BOP Reliability through Industry Collaboration

Maximize BOP assurance and mitigate risks including unplanned BOP stack pulls through collaboration and technology.

Watch On Demand

Digital pressure testing applications on the market regularly pass leaks due to a lack of advanced data analysis. Operators and contractors should be concerned that digital solutions use standard decline analysis to validate high-pressure tests on critical rig equipment and do not account for thermal effects.

This puts operations at risk of harm to the environment, people, and assets because of increased risk of process safety incidents due to lack of leak-detection on BOPs, production trees and well barrier elements.

Digital pressure testing alternatives falsely claim to be predictive by using a curve extrapolation for pressure decline analysis. There is no truly predictive product on the market that utilizes machine learning and artificial intelligence.

This case study shows how IPT’s proprietary algorithms detected potential leaks that were missed by another digital pressure testing vendor for two high-pressure tests.

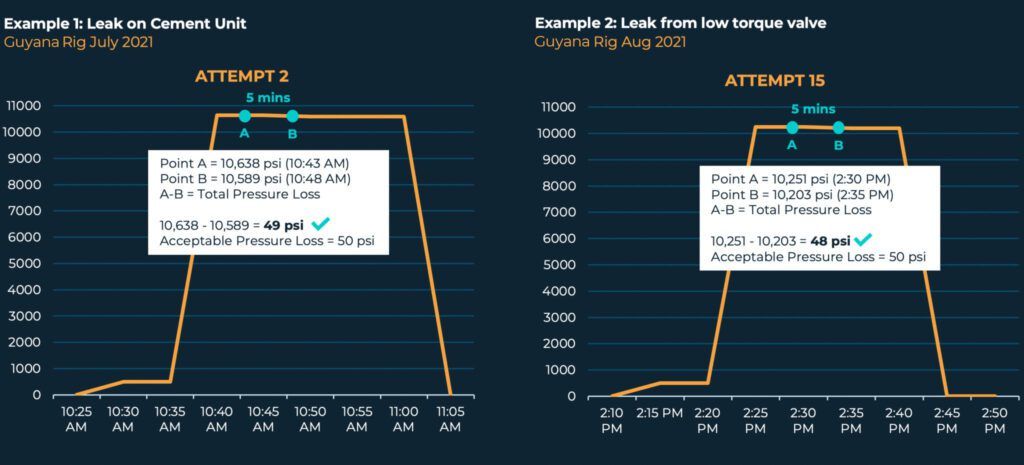

Decline analysis uses a percentage of the required test pressure as the criteria to determine the allowable pressure drop over a given period (typically 5 minutes). For example, if a system has a test pressure of 10,000 psi and the vendor selects 0.5% as the Decline criteria, then the acceptable pressure loss is calculated as follows:

Acceptable Pressure Loss = (Criteria x Test Pressure) = 0.005 x 10,000 psi = 50 psi

The same decline criteria and required test pressure were used in high-pressure tests on a cement unit and a low torque valve shown in Figures 1 and 2, respectively. During the tests, two data points (A and B) were selected five minutes apart by the competitor software. Using the above decline criteria, both tests passed because the respective pressure losses of 49 psi and 48 psi were less than 50 psi.

Using decline criteria alone to validate critical components ignores the thermal effects of pressurization on the system. Pressurization increases the temperature of the system, and the pressure decreases when the system cools during shut in.

It’s the same effect that occurs when car tires lose pressure in the winter. As a result, when the system is shut in to monitor the pressure, part of the pressure drop is due to cooling of the test fluid as the system loses heat to the surroundings. Because of its simplicity, standard digital testing utilizing decline analysis cannot distinguish between pressure loss due to thermal effects and pressure loss due to a potential leak.

Example 1 – Example of competitor digital solution passing a test with pressure loss of 49 psi. This large pressure drop was allowed due to a lack of advanced algorithms, only available through IPT SureTec. SureTec removed the thermal influence and identified a leak on the cement unit.

Example 2 – Example of a competitor digital solution passing a test with a pressure loss of 48 psi. This large pressure drop was allowed due to a lack of advanced algorithms, only available through IPT SureTec. SureTec removed the thermal influence and identified a leak on the lower torque valve.

To demonstrate that competing digital approaches are inadequate for leak detection, the same tests were analyzed using IPT’s proprietary advanced analysis. This analysis uses strict criteria to detect a leak with a high level of confidence.

The IPT analysis failed the same test that passed using a competing digital solution. IPT technology was able to differentiate thermal influences as the test fluid cooled off during testing.

Be sure that your testing on integrity critical equipment and well barrier elements is accurate and effective with advanced leak detection through IPT SureTec Advanced Leak Detection Analysis! Contact us today to learn how our advanced analysis can help you.