Well integrity is determined by the reliability of well barrier elements (WBEs) to prevent the uncontrolled release of fluids from an oil and gas well into the environment. The consequences of the loss of well barrier integrity can be severe, ranging from environmental damage to fatalities. Sustaining well integrity throughout a well life cycle is critical in minimizing risk due to failed WBEs. However, a well’s operating conditions or utilization may change as the well ages, adversely affecting the integrity of critical WBEs. It’s difficult to maintain consistency in well integrity over the years through knowledge transfer and documentation handover among teams. IPT provides a centralized cloud-based platform that manages well integrity data and regulatory compliance through each phase of a well’s life, including drilling, completion, production, workover, intervention, and plug and abandonment.

Construction (Drilling & Completion)

During drilling and completion, improve well integrity management by designing, planning, testing, and reporting barrier verification test results in one integrated well integrity life cycle management platform for total assurance.

Well Integrity Test Planning

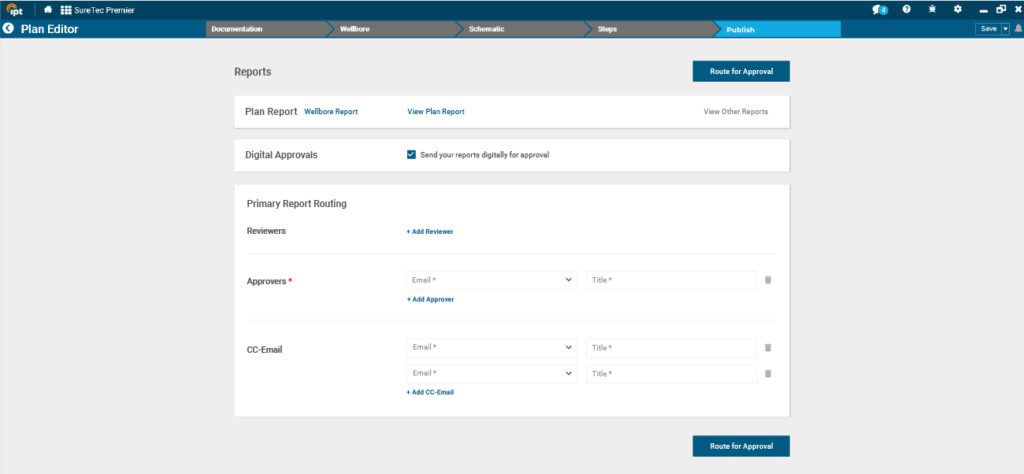

Operators use a cloud-based application to build schematics, wellbore diagrams, and test plans for drilling and completion. The application generates a standardized, detailed test plan report including schematics, criteria, and complete documentation of surface and subsea components to be tested for each well integrity test. The tests plans can be digitally routed for approval and securely stored in the cloud using the Assurance Workflow tool.

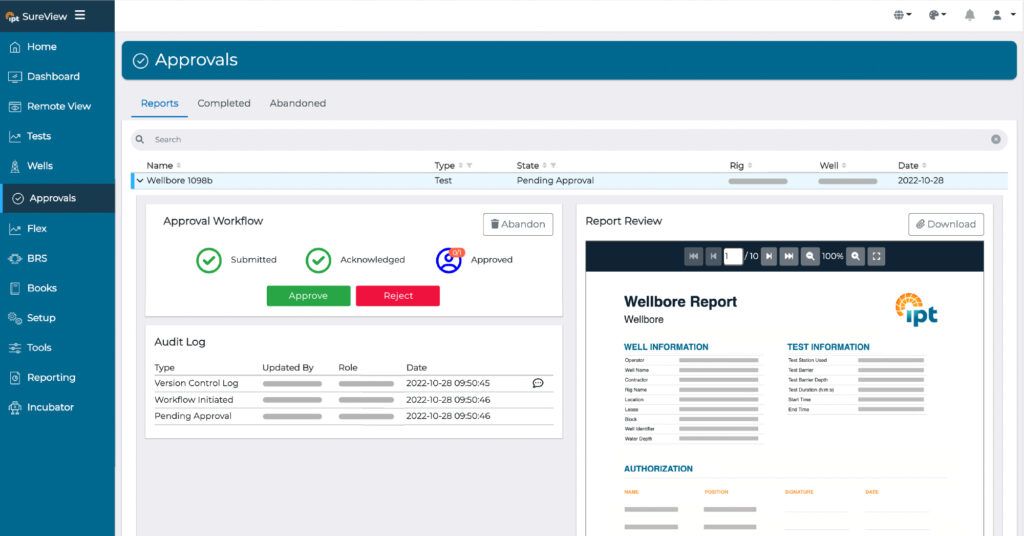

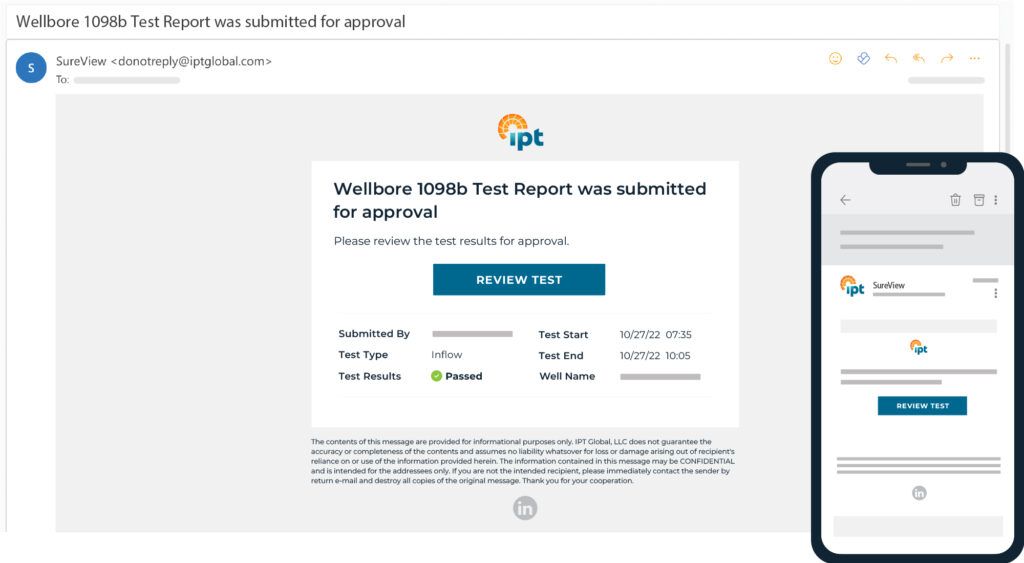

Well Life Cycle Integrity Testing Approval Workflows

The Assurance Workflow tool allows signatories to download and review drilling and completion test plan reports, and it simplifies the gathering of digital approvals via mobile devices. It streamlines collaboration and communication by rerouting rejected test plans and test reports for modifications and final approval.

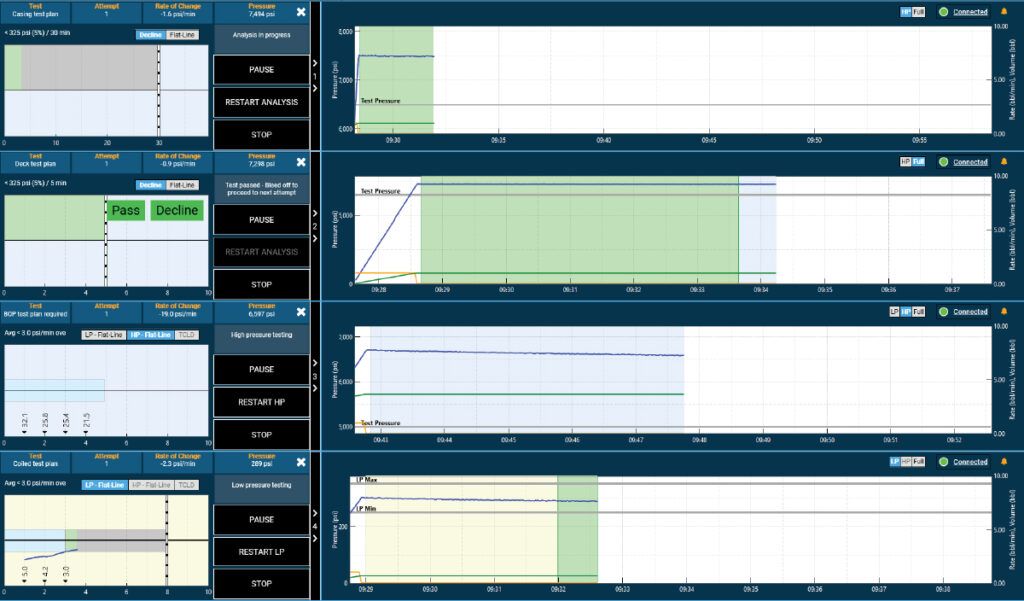

Test Execution

Performing accurate, comprehensive, and efficient integrity tests during drilling and completion is a challenge in high-pressure, high-temperature environments. It requires comprehensive well integrity management software and effective collaboration between the operator and service company performing the tests. An accurate, consistent, and transparent methodology is necessary for validating and managing the integrity of WBEs. IPT’s patented algorithms—including Thermally Compensated Leak Detection evaluate pressure test data based on objective criteria and definitively confirm whether an integrity test passed or failed. Reports for completed tests are automatically uploaded to the cloud and routed for digital approval using the Assurance Workflow tool. The cloud-based platform also provides remote viewing of active tests from anywhere in the world, test data archival and retrieval, and advanced data visualization analysis.

IPT collaborates with operators and contractors on-site and remotely through its industry-leading experts. Field Service Advisors provide on-site integrity test coordination and optimization. Engineers perform post-test reviews to ensure that all components are properly tested. Real-Time Operations Engineers & Advisors (RTOAs) verify that test reports are published properly to assure the traceability of all integrity tests for hand off to the production team. BOP Compliance Surveyors provide third-party equipment inspection and auditing using industry recommended survey and inspection practices.

Maintaining BOP Integrity During Drilling

Blowout preventers (BOPs) serve as a critical secondary barrier during drilling. The challenge for drilling contractors and operators is to know when to repair or replace BOP components to minimize non-productive time (NPT) due to component malfunction or failure. Regulations require operators to periodically pressure test and function test BOP stack components to ensure well integrity. Contractors perform weekly function tests to actuate the rams and annular preventers to ensure they will operate properly in an emergency. The actuation duration and volume of hydraulic fluid required are important indicators of the health of critical BOP components.

IPT engineers monitor and analyze BOP pressure tests, BOP function tests, maintenance, and failure data to gain insight into when and why failures occur. Engineers use data visualization to spot trends in pressure and function test data so that contractors can repair and replace BOP components, when necessary, rather than on an arbitrary schedule as commonly used.

Production

Production has a different set of challenges to maintain well lifecycle integrity while optimizing production. These challenges include complex physical and chemical process changes that occur in the wellbore and surrounding formations. Adding to this complexity, aging oil and gas wells become more prone to corrosion, erosion, and other forms of wear and tear that can compromise well integrity. The production team must decide when to intervene and extend production or retire a well that is no longer safe or economically viable.

The centralized well lifecycle integrity management solution ensures complete documentation handover to the production team. It gives the team access to WBE integrity data and reports for transparency and compliance. It also allows the team to compare integrity data with other wells to identify potential issues before they become major problems.

Workovers & Interventions

Integrity testing of well components during light and heavy (workover) interventions presents different challenges for well lifecycle integrity management than testing during well construction. As interventions have a shorter duration of a few weeks, component integrity tests are carried out more frequently compared to the construction of a well. Many offline integrity tests are performed simultaneously on the deck of the intervention vessel to eliminate delays once the crew connects to the well.

Multi-testing capability enables the crew to perform integrity tests thoroughly and efficiently to avoid delays in critical path operations that would be costly for both the intervention service company and the operator. After the intervention is completed, there is traceability of all well integrity tests to hand off to the production team and for compliance with local regulatory bodies.

Plug & Abandonment

Compliance regulations that govern plug and abandonment regulations can vary across jurisdictions, which makes compliance challenging for operators with international assets. Operators must comply with these regulations to ensure safe and environmentally responsible operations. Regulations typically cover a range of areas, such as casing and cementing requirements, pressure testing procedures, and monitoring and reporting requirements.

A critical aspect of compliance with plug and abandonment regulations is the need for integrity management of well barrier elements (WBE). Well integrity management software can be used to provide historical data on each WBE. This data can help operators identify any potential issues that may arise during the abandonment process, such as defective equipment or oil leaks. All P&A activities can be tracked and documented with integrity management software providing a comprehensive record of the operation ensuring compliance with regulations are met. By having this data, operators can take steps to ensure that the well is abandoned safely and mitigate risks.

Contact Us

Ensure the reliability of well barrier elements over the entire well life cycle. Implement IPT’s centralized cloud-based platform to manage well integrity data, regulatory compliance, and integrity testing through each phase of the well’s life cycle. With IPT, you can improve well integrity management during drilling and completion, maintain BOP integrity, optimize production while ensuring well integrity, and comply with plug and abandonment regulations. Act now to minimize risk and ensure the safety and sustainability of your operations. Contact us for more information on managing integrity throughout the well lifecycle.